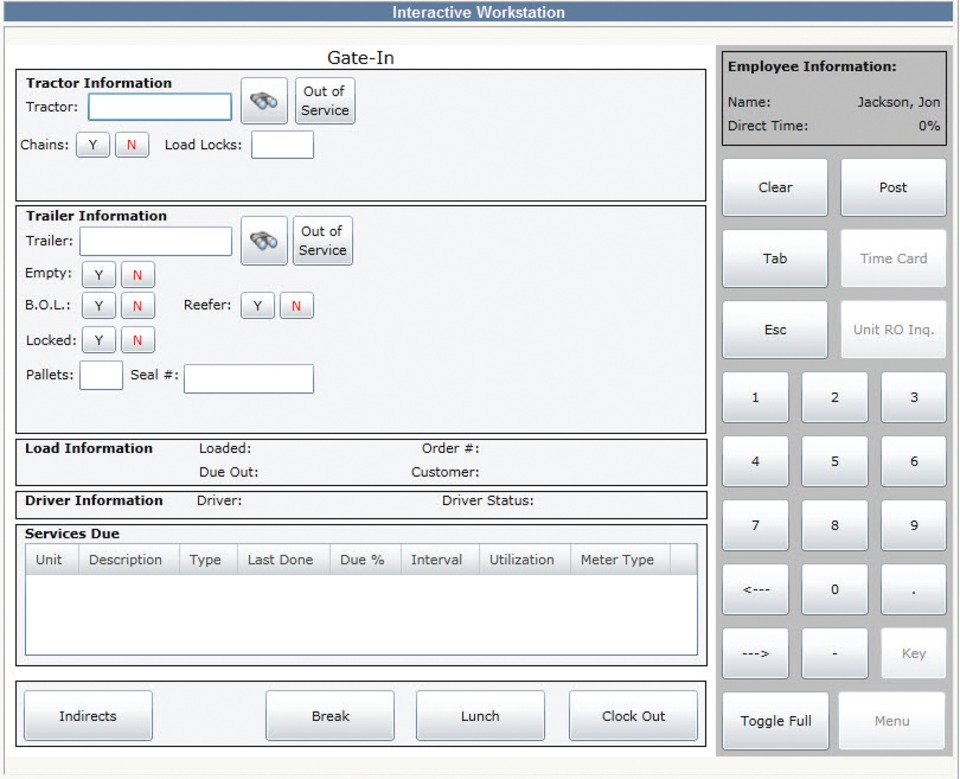

Vehicle diagnostics and maintenance management Business analytics and reports “Information together is critical for our daily operation because it gives a synopsis of what is happening. TrimFleet allows us to document exactly when and where the mixer trucks are in case a dispute over timing or questions arise around delivery. Aug 09, 2012 Maintenance Software at This video is a Quick Demo of TATEMS Fleet Maintenance Software. You can download a 30 day free tri.

- Tmt Maintenance Software Manual Download

- Tmt Fleet Maintenance Software

- Small Business Maintenance Software

If you’re reading this, the answer is more than likely “Yes.”

- Page 1 mastiff 300/300m swing gate opener user manual.; page 2: table of contents index general safety precaution installation a. Standard installation b. Dimension chart c. Motor fixing d. Wire connection e. Emergency release f. Mechanical stopper adjustment technical features a. Technical features b. Dimension maintenance.

- Fleet maintenance software schedules when vehicle maintenance should occur. Avoid expensive repairs and downtime due to missed maintenance. Have a detailed history of fleet maintenance performed, how much it cost and who did the work. Achieve the longest life possible from your vehicles.

- Connectivity shall fully implement TMT within three (3) months of the successful development and installation of “AOPS/TMT Lite” (estimated deployment in Summer 2004). This software solution will enable bandwidth-constrained units to make AOPS and TMT entries locally and later synchronize with the AOPS/TMT central database. A listing of these.

- Trimble (NASDAQ: TRMB) introduced today its new TMT ServiceConnect module, enabling fleet shops using Trimble’s TMT Fleet Maintenance (TMT) software to be connected to more than 4,500 medium and heavy duty service locations, including many Original Equipment Manufacturers (OEM) dealers, throughout North America.

- View and Download Tmt Mastiff 300m user manual online. Swing gate opener. Mastiff 300m Gate Opener pdf manual download. Also for: Mastiff 300.

Repairs and maintenance account for an average of 9% of total fleet costs, and a full 60% of trucking companies are still using manual processes to track fleet maintenance—if they are tracking it at all. Whether you’ve given it much thought or not, chances are good that you could benefit from fleet maintenance software.

Many small fleets ignore non-critical maintenance and simply hope to avoid compliance-related fines and costly breakdowns. Larger fleets are more likely to use some sort of maintenance software. However, in both cases, opportunities to reduce costs and risks are being missed.

Fleets with more than 150 assets have historically been the key adopters of solutions like our TMT Fleet Maintenance software, which integrates with almost any other fleet management system on the market. Now, fleets with fewer than 150 trucks or pieces of equipment can benefit, too. Subscription-based solution, TMW FleetCheck, features affordable, rapid implementation and operates based on expert analysis of fleet needs gathered from years of industry experience.

Download our free whitepaper, “20:1 Fleet Maintenance Solutions,” now for help in calculating a modern fleet maintenance IT solution.

Three Reasons to Use Fleet Maintenance Software

Tmt Maintenance Software Manual Download

Regardless of your company size, TMS or fleet management model, adopting fleet maintenance software is a win-win for several reasons:

1. Greater visibility into maintenance schedules, asset maintenance history and maintenance costs

Whether you outsource all of your maintenance, some of it or maintain all your own vehicles, it allows for easy tracking of key information. You can tap into pre- and post-trip data, as well as fault code, meter and mileage data. Individual vehicle repair histories can also be logged, giving insight into repair frequency, quality and other details.

- If you outsource maintenance, it becomes easier to answer: “How good is the maintenance I’m getting?” “Am I compliant?” “What is my planned maintenance schedule?”

- If you conduct your own maintenance, it becomes easier to answer: “Are we repairing trucks efficiently?” “How are we managing our inventory and maintenance schedules?” “Will we have the right parts on hand?

2. The ability to predict maintenance needs and prevent breakdowns

Basically you conduct vehicle maintenance because you don’t want to wait until something breaks to make a repair. When you wait, you incur costs to fix the problem and experience losses related to downtime, missed deadlines and--in some cases--fines. Software with predictive maintenance capabilities allows trucking companies to proactively estimate when parts might fail and create maintenance schedules to keep their assets in service and reduce the number of on-the-road citations.

3. Easier management of warranties

No matter how you currently track fleet upkeep, software makes it easy to document work that may be required to maintain your OEM warranties. Additionally, TMW Solutions follows aftermarket warranties on your trucks and individual replacement parts—a taxing endeavor via manual processes.

Tmt Fleet Maintenance Software

Why Fleet Maintenance Software Now?

Right now is a great time to think about how your fleet could be more proactively and cost-effectively maintained. If you haven’t used this type of software in the past, but you’re at a tipping point where manual maintenance logging and scheduling processes no longer make sense, consider whether our fleet maintenance software could boost your bottom line, regulatory compliance and peace of mind.

If you’ve operated a large fleet for some time, but don’t use asset maintenance software, consider if you could get more out of your capital and lifecycle investments with a comprehensive view of maintenance operations. In either case, the opportunity to improve your efficiency with better data access and analytics is here.

Remember to download our free whitepaper, “20:1 Fleet Maintenance Solutions,” it’s yours today for help in calculating a modern fleet maintenance IT solution.

Have questions about TMW’s fleet maintenance options? Feel free to reach out and start a discussion. We’re here to help you win. And don’t forget to subscribe to our blog today. You’ll receive one weekly update in your inbox.

Transformation of sensor signals into stable and standardized output signals for all industries

Unsurpassed reliability, accuracy and long-term stability in critical processes over all industries. The configurable transmitter not only transfers converted signals from resistance thermometers (RTD) and thermocouples (TC), it also transfers resistance and voltage signals. The standardized output signal used for process measurement is a 4 to 20 mA signal. Swift and easy operation, visualization and maintenance by PC using operating software.

Additional components

RN221N

Active barrier with optional HART® diagnosisActive barrier with power supply for safe separation of 4...20 mA current circuits

RIA14

Loop-powered field indicatorExcellent readable indication of a 4…20 mA signal on-site for a better process overview!

RMA42

Process transmitter with control unitUniversal transmitter, loop power supply, barrier and limit switch in one device!

RB223

Loop powered passive barrierOne or two-channel barrier for the safe separation of 4...20 mA standard signal circuits

High accuracy in total ambient temperature range

Ex certification: ATEX Ex ia and dust ex zone 22 in compliance with EN 50281-1; FM IS; CSA IS

Fault signal on sensor break or short circuit, NAMUR NE 43 compliant

EMC to NAMUR NE 21, CE

Configuration...

PC programmable (PCP) temperature head transmitter for converting various input signals into a scalable 4 to 20 mA analog output signal

Input: Resistance thermometer (RTD), thermocouple (TC), resistance transmitter (Ω), voltage transmitter (mV)

...

Details

Head transmitter

1 x RTD, TC, Ohm, mV

1 x analog 4...20 mA

8...35 V DC (standard-version)

8...30 V DC (Ex-version)PCP (pc-programmable)

Terminal head form B

(Pt100, -50...200 °C) <= 0,2 K

(Pt100, -58...392 °F) <= 0,4 °Fyes

UL Ex IS, NI

Marine approval

GOST Ex i

FM IS,NI,Class I,Div.1+2,Group ABCD

CSA IS,NI,Class I,Div.1+2,Group ABCD

ATEX II3G Ex nA IIC T4/T5/T6

ATEX II1G EEx ia IIC T4/T5/T6

ATEX II3D

ATEX II1G EEx ia IIC T6, II3D

ATEX II3G Ex nA IIC T6, II3D

FM+CSA IS,NI,Class I,Div.1+2,Group ABC

CSA General Purpose

NEPSI Ex ia IIC T4-T6

NEPSI Ex nA II T4-T6

GL (German Lloyd)

- Temperature head transmitteriTEMP PCP TMT 181

Universal head transmitter for resistance thermometers (RTD),

thermocouples, resistance and voltage transmitters, settable using aPC,

for installation in a sensor head (Form B) - ReadWin® Quick Setup

Operating Manual

ReadWin® Quick Setup Temperature

PC Software - iTEMP® PCP TMT 181Manuale operativo

iTEMP® PCP TMT 181

- Operating Manuals ReadWin 2000 (GB)

Operating Manuals ReadWin 2000

- iTEMP® TMT181 PCPOperating instructions

Temperature head transmitter

08/10 - ATEX Safety instructions iTEMP®

Temperature head transmitter iTEMP® TMT181, TMT187, TMT188 Safety

instructions for electrical apparatus certified for use in explosi

on-hazardous areas (II 3D). - iTEMP TMT181, TMT187, TMT188ATEX:II 1G: Ex ia IIC T6/T5/T4Safety Instructions

Safety instructions for electrical apparatus certified for use in

explosion-hazardous areas. - Temperature transmitter0ExiaIICT6...T4 XSafety Instructions

Safety Instructions EAC: 0ExiaIICT6...T4 X, iTEMP TMT181, TMT182,

TMT187, TMT188 temperature transmitter - ATEX SicherheitshinweiseATEX Safety instructions

PC-programmierbarer Temperaturkopftransmitter iTEMP PCP TMT181; Montage

im Anschlusskopf Form B - iTEMP TMT181, TMT187/188, TMT182ATEX:II 3D: Ex ia IIIC T85 °C...T120 °C DcII 3D: Ex tc IIIC T120 °C DcII 3G: Ex nA IIC T6...T4 GcSafety Instructions

Safety instructions for electrical apparatus certified for use in

explosion-hazardous areas. - Control Drawing FM iTEMP 181, TMT187, TMT188

Temperature head transmitter iTEMP TMT181, TMT187, TMT188

Installation Notes for hazardous locations - Control Drawing CSA iTEMP® 181, TMT187, TMT188

Temperature head transmitter iTEMP® TMT181, TMT187, TMT188

Installation Notes for hazardous locations - Control drawing FM iTEMP® TMT181, TMT187, TMT188

Temperature head transmitter iTEMP® TMT181, TMT187 TMT188

Installation Notes for hazardous locations - 温度测量

过程工业用温度传感器和温度变送器

12/14 - Pomiar temperatury

Czujniki i przetworniki pomiarowe

do kontroli przemysłowych procesów technologicznych10/14 - Измерение температуры

Датчики температуры и преобразователи для любых

отраслей промышленности.06/13 - Catálogo medición temperatura

Termómetros y transmisores para la industria de proceso

04/18 - Mesure de température

Capteurs et transmetteurs pour les industries de process

04/18 - Temperature measurement

Thermometers and transmitters for the process industry

04/18 - Misura della temperatura

Termometri e trasmettitori

per l'industria di processo04/18 - Temperature measurement

Thermometers and transmitters for the process industry

03/19 - Temperaturmesstechnik

Thermometer und Transmitter für die Prozessindustrie

03/19 - Sıcaklık Ölçümü

Proses endüstrisi için termometreler ve transmiterler

03/13 - Field of activities FA Temperature measurement

Thermometers and transmitters for the process industry

03/13 - Измерение температуры

Ключевые особенности термометров Endress+Hauser для нефтегазовой отрасли

08/11 - Инженерные решения по термометрии

Специальные решения по термометрии для химической и

нефтеперерабатывающей промышленности04/10 - Ein Tankschiff schlägt Wellen

Solutions und Messtechnik (Füllstand und Temperatur). Problemstellung:

altes Schiff wurde umgebaut zu einem modernen, alte Technikdurch

neue ersetzt. E+H = Komplettlieferant: Gesamtverantwortung des

Projektmanagements für Engineering-Dienstleistungen inklusive

Programmierung der Steuerung und Visualisierungssystem, Lieferung der

Steuerung, Lieferung der Sensoren und Inbetriebnahme des gesamten

Systems. Erfasst u. visualisiert die Tankbefüllung sowie das

Tankmanagement und den Tiefgang des Schiffes. Automatische

Auswertung der Ladung. Vorteil: Zeitersparnis, Eliminierung von

Fehlerquellen.01/11 - A river barge makes waves

Befrag AG´s inland waterway tanker Brienzersee stationed in Birsfelden,

Switzerland, transports liquid goods reliably and safely over the Rhine

river.01/11 - Temperature transmitters and components (IN)

A new generation of transmitters and components offers simple

operation and greater control03/11 - Kopftransmitter TMT181

Temperatur - Kopftransmitter (2-Draht) mit programmierbarem

Messbereich

und kundenspezifischer Linerarisierung, zur Montage im Anschlusskopf

Form DIN B12/12 - ACCESSORIES: TC INSERT, head transmitters, Process RTD Direct contact, Process RTD General purpose, Process RTD Heavy duty, Process RTD Hygienic, Process TC direct in contact, Process TC General purpose, Process TC Heavy duty

Product Code: TMT85-, TPC100-, TR10-, TR11-, TR12-, TR13-, TR15-, TR24-, TR61-, TR62-, TR63-, TR65-, TR66-, TR88-, TSC310-, TST310-, TMT84-, TMT82-, TMT188-, TMT187-, TMT182-, TMT181-, TC88-, TC66-, TC65-, TC63-, TC62-, TC61-, TC15-, TC13-, TC12-, TC10-

Declaration Number: HE_00237_03.15

Manufacturer Specification: Explosion protection, EMC - head transmitters

Product Code: TMT181-, TMT181L-

Declaration Number: HE_00462_01.17

Manufacturer Specification: RoHS - head transmitters

Product Code: TMT181-, TMT187-, TMT188-

Declaration Number: EC_00181_01.16 - ACCESSORIES, DIN Rail Transmitter, Field transmitter, head transmitters

Product Code: TMT127-, TMT128-, TMT142-, TMT162-, TMT180-, TMT180L-, TMT181-, TMT181L-, TMT182-, TMT182L-, TMT187-, TMT188-, TMT80-, TMT82-, TMT84-, TMT85-, OTMT127-, OTMT128-, OTMT187-, OTMT188-, OTMT80-, OTMT82-, OTMT84-, OTMT85-, TID10-, TMT111L-, TMT112-, TMT112L-, TMT121-, TMT121L-, TMT122-, TMT125-

Declaration Number: EC_00567_01.17 - head transmitters

Product Code: TMT181-, TMT182-, TMT187-, TMT188-

Declaration Number: EC_00160_01.16 - head transmitters

Product Code: TMT181-, TMT187-, TMT188-

Declaration Number: EC_00321_01.16 - head transmitters

Product Code: TMT180-, TMT181-, TMT182-

Region/Country: China

Approval Agency: ACMA

Approval Number: MD-17038A/09/EN - DIN Rail Transmitter, Field transmitter, head transmitters, RTD-thermometer, Process TC Heavy duty, Process RTD Heavy duty, process displays, power supply and barrier, contactors / transmitters

Product Code: TMT85-, TMT84-, TMT82-, TMT80-, TMT188-, TMT187-, TMT182-, TMT181-, TMT180-, TMT162-, TMT142-, TMT128-, TMT127-, TMT125-, TMT122-, TMT121-, TMT112-, TMT111-, TTR35-, TTR31-, TMT162R-, TMT162C-, TMT142R-, TMT142C-, TMR31-, TMR35-

Region/Country: Russia (TR CU)

Approval Agency: EAC

Approval Number: TC № RU D-DE.AG95.B.00650 - DIN Rail Transmitter, Field transmitter, head transmitters, Process RTD Heavy duty, Process TC Heavy duty

Product Code: TMT82-, TMT80-, TMT188-, TMT187-, TMT182-, TMT181-, TMT180-, TMT162R-, TMT162C-, TMT142R-, TMT142C-, TMT128-, TMT127-, TMT122-, TMT121-, TMT112-, TMT111-

Region/Country: Russia (TR CU)

Approval Agency: EAC

Approval Number: TC BY_112 11.01. TP020 003 126 - head transmitters

Product Code: TMT188-, TMT187-, TMT181-

Region/Country: USA, Canada

Approval Agency: CSA

Category: I/1,2/ABCD

Protection: NI, IS, GP - head transmitters

Product Code: TMT181-, TMT187-, TMT188-

Region/Country: China

Approval Agency: NEPSI

Protection: Ex ia IIC T6...T4 Ga/Gb - head transmitters

Product Code: TMT188-, TMT187-, TMT181-

Region/Country: Europe (ATEX)

Approval Agency: ZelmEx

Category: II1G

Protection: Ex ia IIC T6 - DIN Rail Transmitter, Field transmitter, head transmitters, Process RTD direct in contact, Process RTD Heavy duty

Product Code: TMT85-, TMT84-, TMT82-, TMT188-, TMT187-, TMT182-, TMT181-, TMT162-, TMT142-, TMT128-, TMT127-, TMT125-, TMT122-, TMT121-, TMT112-, TMT111-

Region/Country: Russia (TR CU)

Approval Agency: EAC

Protection: Ex d IIC T6...T4 Gb, Ex tb IIIC Txxx°C Db, Ex ia/d [ia] IIC T6...T4 Gb - head transmitters

Product Code: TMT181-, TMT187-, TMT188-

Region/Country: China

Approval Agency: NEPSI

Protection: Ex nA IIC T6...T4 Gc - head transmitters

Product Code: TMT188-, TMT187-, TMT181-

Region/Country: USA

Approval Agency: FM

Category: I/1,2/ABCD

Protection: NI, IS, AEx - DIN Rail Transmitter, Field transmitter, Low cost RTD General purpose, Process RTD Direct contact, Process RTD Explosion proof, Process RTD General purpose, Process RTD Heavy duty, Process RTD Hygienic, Process RTD direct in contact, Process TC Explosion proof, RTD complete assembly, RTD thermometer Zone '0', RTD-thermometer, head transmitters

Product Code: TR44-, TR45-, TR47-, TR48-, TSM187-, TSM470-, TSM487-, TST310-, TST40N-, TST410-, TST414-, TST41N-, TST90-, TR15-, TMT121-, TMT122-, TMT127-, TMT128-, TMT162-, TMT180-, TMT181-, TMT182-, TMT188-, TR10-, TR11-, TR12-, TR13-

Region/Country: China

Approval Agency: NEPSI

Approval Number: CN_SMB_2004-T180 - DIN Rail Transmitter, Field transmitter, head transmitters

Product Code: TMT85-, TMT84-, TMT82-, TMT80-, TMT188-, TMT187-, TMT182-, TMT181-, TMT180-, TMT162-, TMT142-, TMT128-, TMT127-, TMT125-, TMT122-, TMT121-, TMT112-, TMT111-

Region/Country: Russia

Approval Agency: Rosstandart

Approval Number: OC.C.32.004.A NO 74639 - ACCESSORIES: BAR STOCK THERMOWELL, ACCESSORIES: PIPE THERMOWELL, DIN Rail Transmitter, Field transmitter, head transmitters, Process RTD Heavy duty, Process TC Heavy duty

Product Code: TMT112-, TMT142-, TMT162-, TMT181-, TMT182-, TMT84-, TMT85-, TR61-, TR62-, TR63-, TR65-, TR66-, TMT111-, TC66-, TC65-, TC63-, TC62-, TC61-, TA576-, TA570-, TA562-, TA550-, TA535-, T82-

Approval Agency: RM RS - head transmitters

Product Code: TMT180-, TMT181-, TMT182-, TMT187-, TMT188-

Region/Country: International

Approval Agency: DNVGL - RTD-thermometer, process displays, Memo-Graph, Field transmitter, Ecograph, contactors / transmitters, head transmitters, DIN Rail Transmitter

Product Code: TMT162-, TMT142-, RIA14-, RIA16-, RIA45-, RIA46-, RMA42-, RSG35-, RSG45-, TMR31-, TMR35-, TMT85-, TMT84-, TMT82-, TMT188-, TMT187-, TMT182-, TMT181-, TMT128-, TMT127-, TMT122-, TMT121-, TMT112-, TMT111-, TMT180-

Region/Country: Canada, USA

Approval Agency: UL

(4 screws, 6 springs, 10 spring rings)

according to IEC 60715 fortemperature head transmitters.

for PC-programmable devices.set-up programme+interface cable for PCwith USB-Port.

Application: E+H Head transmitter.Housing: Alu IP66, 100x100x60mm.

Success stories

Iplom enhances catalyst life, process safety and efficiency

Iplom SpA sought to optimize its refining process to extend catalyst life and to increase safety in a hydrodesulfurization (HDS) application through precise 3D temperature profiling.

Automated inline self-calibration at Lonza

Automated inline self-calibration at Lonza for full monitoring throughout bioprocess

Optimized logistics concept for tank systems

We implemented a highly effective logistics concept at chemicals distributors Brenntag Schweizerhall AG's Basel site.

Speed and accuracy help to meet stringent quality demands

Chr. Hansen eased temperature monitoring and calibration, both critical to the UHT treatment of the nutrient solution, using iTHERM TM411 temperature sensor

Small Business Maintenance Software

Standardized temperature measurement at DMK in Germany

Learn from this video how DMK ('Deutsches Milchkontor GmbH') in Hohenwestedt/Germany was able to reduce its cost by standardizing temperature measurement with the hygienic line iTHERM TM411.

Protection of pumps... and people

Adding a few sensors to a pump system can help make pumps run more efficiently and help discover problems before they get too serious – and, they may also save a life

22.10.2019 - 25.10.2019

With the help of actual hands-on tasks you will learn how PROFIBUS fieldbus technology works in detail.

16.03.2020 - 20.03.2020

With the help of actual hands-on tasks you will learn how PROFIBUS networks are installed in detail. The emphasis is on the correct installation and usage of tools.

22.06.2020 - 26.06.2020

With the help of actual hands-on tasks you will learn how PROFIBUS fieldbus technology works in detail. At the end of the course you will be able to design and commission a PROFIBUS fieldbus network.

22.07.2020 - 23.07.2020

You will learn how to implement WirelessHART successfully and where WirelessHART can add value to an existing plant. You will actually build a WirelessHART network with components from Endress+Hauser.